Our Projects

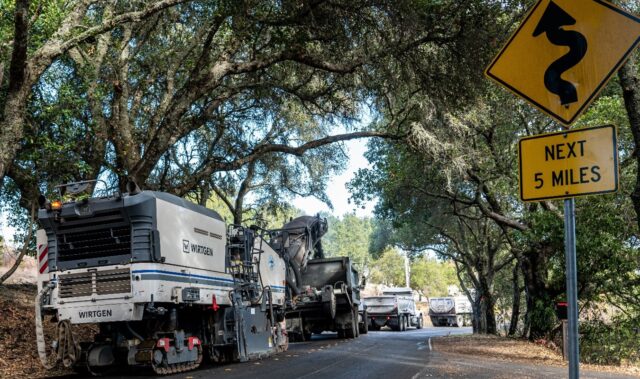

Milling & P3 Smoothness Solutions – 3D Milling, Micro Milling

Rte 52 – San Diego

The scope of this work was to repair massive settling of the roadway causing a danger to the driving public. The cause of the settlement is due to the roadway being built over an area that was once a landfill, resulting in voids under the structure of the road. It was our intent and design, working hand-in-hand with CalTrans, to utilize our P3 applications.

The first phase of this project was to correct extreme roughness to make the roadway safe for traveling public during compaction grouting by utilizing an inertial profiler and LiDAR scanner. The data was used to identify locations requiring deeper cut depths, locations with long wavelengths that the 30’ ski couldn’t correct and any cross slope or draining issues, such as, puddling in lanes. After first phase was completed utilizing the strategy with a micro mill, the roadway improved by 29%. The roadway was then paved in two lifts, first lift of .12’ HMA and second lift of .20’ RHMA. Inertial profile data was collected during paving on both lifts to ensure no corrections to first lift would be needed to meet smoothness on final surface. the smoothness achieved on final surface, large variable cuts, improvements on long wavelengths and corrections to cross slopes could not have been accomplished without the use of PRS provided design model and 3D automated machine control.

Ready?

We're here and we are ready.